Profession

Training, Study

Enlarge picture: Move the

mouse pointer to the picture

and then the left mouse button

to press. At the top

find a comment

Am there on drilling a test board

Guidelines apprenticeship year

Report portfolio section

Profession certificate

Film: Camera

deflection

Film: Camera

clock generator

Diploma

Vidicon camera

SW multi standards

Picture gallery: Training Philips

So we started on 15.08.1974 morning at the company Philips. Then we

were also told that Philips in Wetzlar produces top-end car radios and

Schnittbandkern- transformers. After the presentation of all trainers

and some other people, a group photo was taken with all trainees and

the trainers. Then it went straight into a workshop with vices, turning

and milling machines and other machines for metal and plastic

processing. First, we were given a work coat with the Philips logo (only

real with the four stars) and important information about possible

dangers when working with metal. e.g. The trainee colleagues with the

longer hair had to wear a hairnet when they had to work on the drill

press.

Then we got a piece of steel and we were shown how a file looks and

Right next to our workshop was a football field, then there was an outdoor pool and

in the cafeteria above the canteen were table tennis tables. These were worked

together. About once a week they were set up and then some employees played

table tennis after work.

And under the canteen, in the basement, was a bowling alley. By the way, the

employees were able to use the swimming pool for free in the summer with the

family on weekends. Also on the football field were games between e.g. Footballers

of Leitz and Philips or other teams discharged.

In the next six months, we also got to know the electric current and the voltage

and the resistance. When you do all three together, something like Ohm's Law

comes out. Of these laws and rules, there are more in the business. The dangers of

the electric current were

taught to us. In the first

year of training, three of

us spent a week on

educational leave. Back

then, it was at company

costs in the vicinity of

Kassel to Jugendhof

Dörnberg. There we did

everything for a week

except playing with

electrics. Another

educational leave with

trainees from Philips took

place about 1 year later in

Malente.

After one year the first intermediate examination took place. The apprentices from Philips and Leitz have made common cause. Otherwise we only saw the

colleagues from Leitz in the vocational school. Once at the exams either the Leitz trainees came to Philips or the apprentices from Philips went to the

Hausertorwerk to Leitz. When the exam was over, it was also in the training a little more electronic. We were also transferred from the training workshop to

other departments of the company for 3 months. The departments I was allowed to get to know were the manufacturing, quality control car radio, quality

control transformer, metering department and the department where all Philips products were repaired. The spectrum ranged from the steam iron on

television to the Ladyshave. We also had a point of sale where Philips products could be bought. Everything that we had learned in the second year of training

was asked at the second examination for the communications equipment mechanic. After this test, it was the final spurt. We were allowed to learn a lot and

also make mistakes, from which one knows, as everyone knows, the most.

After three and a half years, the final exam was in the house. As expected, all have passed and may now call themselves Funkelektronikerin or

Funkelektroniker. Now we could actually work normally. But young men now threatened another problem, the Army. Some of them reluctantly went to the

German Armed Forces, others did civilian service and I had to be put off for a year to get a baccalaureate. And so I quit after about half a year and made at

the FOS (Technical College) in the Werner von Siemens school in Wetzlar my high school diploma. In this one year FOS especially the math was new.

Differential calculus and integral calculus and matrix calculus were new at first. We even had religion. And in German we had to write a half-year paper on the

subject of "Consumption Terror". Then you see the advertising and the very large range of products with completely different eyes.

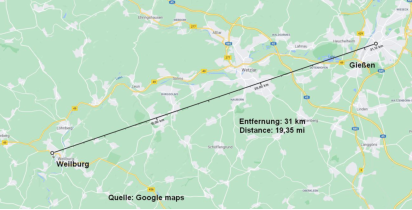

After the FOS I enrolled at the University of Applied Sciences Gießen for the degree program Electrical Engineering specializing in communications and

microprocessor technology. Actually, I should immediately after the FOS report to the mustering authority. But I totally forgot that through all the work.

The first three semesters were decidedly theoretical and did not bring any new practical insights to those who had undergone training.

The magnetic and electric fields in theory are in my opinion not exactly easy and in the daily work not necessarily required. The last three semesters were

also a bit more practical. Then came the thesis. I chose one that interested me the most. She called herself "Designing and Building a Multinormal Black and

White Vidikon Camera". The multi-standard refers to different frame rates and different line numbers. And a vidicon is a picture tube with e.g. 1 inch

diagonal.

© DL4FG Weilburg

German

The work was supervised by Prof. G. Schmidt. The image on the page

shows the camera in the open state. In order to hide the wild wirred

connection from prying eyes an inconspicuous U-shaped aluminum

sheet was slipped over the wild wirred connection and screwed. Then

it can happen that a nice student colleague sees the thing and thinks,

what he would have done in four weeks at the most. I think that

everyone has ever stumbled upon this kind of expert. After I had my

work in a 20-minute presentation in the NT seminar and the oral exam

behind me, the matter was also happily ended. Incidentally, I was

never in the Army because I was retired.

What do you want to do with someone like me? I had to wear contact

lens wearers. And those people did not want them in the Army.

Technical College (today THM) in Gießen (SOURCE Google Images)

From the work coat

directly to the website

Sewn.

Philips logo of 1974

how to operate it. And then for the first half of the year we were busy with

filing, sawing, turning, milling, drilling, and so on. Parallel to the work, we also had

to keep a report booklet in which the typeface should be a standard font. Of

course, there was once a week in the vocational school (Werner von Siemens

School). So we did not have any block lessons. The trainees were about half tool

makers and the other half radio electronics technicians and a technical

draughtswoman.

The apprentices, the industrial clerk / woman learned, I have not seen after the

group picture. Gradually we got to know the company. Right next to our workshop

was a football field, then there was an outdoor pool and in the cafeteria above

the canteen were table tennis tables. These were worked together. About once a

week they were set up and then some employees played table tennis after work.

Training contract

Philips 1974

© DL4FG WEILBURG

Am there on drilling a test board

Guidelines

apprenticeship year

Profession certificate

Film: Camera

deflection

Slide: Camera

clock generator

Vidicon camera

SW multi standards

So we started on 15.08.1974 morning at the company

Philips. Then we were also told that Philips in Wetzlar

produces top-end car radios and Schnittbandkern-

transformers. After the presentation of all trainers

and some other people, a group photo was taken with

all trainees and the trainers. Then it went straight

into a workshop with vices, turning and milling

machines and other machines for metal and plastic

processing. First, we were given a work coat with the

Philips logo (only real with the four stars) and

important information about possible dangers when

working with metal. e.g. The trainee colleagues with

the longer hair had to wear a hairnet when they had

to work on the drill press. not have any block lessons.

The departments I was allowed to get to know were the manufacturing,

quality control car radio, quality control transformer, metering department

and the department where all Philips products were repaired. The spectrum

ranged from the steam iron on television to the Ladyshave. We also had a

point of sale where Philips products could be bought. Everything that we had

learned in the second year of training was asked at the second examination

for the communications equipment mechanic. After this test, it was the final

spurt. We were allowed to learn a lot and also make mistakes, from which one

knows, as everyone knows, the most.

After three and a half years, the final exam was in the house. As expected,

all have passed and may now call themselves Funkelektronikerin or

Funkelektroniker. Now we could actually work normally. But young men now

threatened another problem, the Army. Some of them reluctantly went to

the German Armed Forces, others did civilian service and I had to be put off

for a year to get a baccalaureate. And so I quit after about half a year and

made at the FOS (Technical College) in the Werner von Siemens school in

Wetzlar my high school diploma. In this one year FOS especially the math

was new. Differential calculus and integral calculus and matrix calculus were

new at first. We even had religion. And in German we had to write a half-

year paper on the subject of "Consumption Terror". Then you see the

advertising and the very large range of products with completely different

Profession

Training, Study

Diploma

German

eyes.

After the FOS I enrolled at the

University of Applied Sciences

Gießen for the degree program

Electrical Engineering specializing

in communications and

microprocessor technology.

Actually, I should immediately

after the FOS report to the

mustering authority. But I totally forgot that through all the work. The

first three semesters were decidedly theoretical and did not bring any new

practical insights to those who had undergone training. The magnetic and

electric fields in theory are in my opinion not exactly easy and in the daily

work not necessarily required. The last three semesters were also a bit

more practical. Then came the thesis. I chose one that interested me the

most. She called herself "Designing and Building a Multinormal Black and

White Vidikon Camera". The multi-standard refers to different frame

rates and different line numbers. And a vidicon is a picture tube with e.g. 1

inch diagonal. he work was supervised by Prof. G. Schmidt. The image on the

page shows the camera in the open state. In order to hide the wild wirred

connection from prying eyes an inconspicuous U-shaped aluminum sheet was

slipped over the wild wirred connection and screwed. Then it can happen

that a nice student colleague sees the thing and thinks, what he would have

done in four weeks at the most. I think that everyone has ever stumbled

upon this kind of expert. After I had my work in a 20-minute presentation

in the NT seminar and the oral exam behind me, the matter was also happily

ended. Incidentally, I was never in the Army because I was retired. What

do you want to do with someone like me? I had to wear contact lens

wearers. And those people did not want them in the Army.

Technical College (today THM) in Gießen

(SOURCE Google Images)

From the work coat

directly to the website

Sewn.

Philips logo of 1974

Then we got a piece of

steel and we were shown

how a file looks and how

to operate it. And then

for the first half of the

year we were busy with

filing, sawing, turning,

milling, drilling, and so on.

Parallel to the work, we

also had to keep a report

booklet in which the

typeface should be a

standard font. Of course,

there was once a week in

the vocational school

(Werner von Siemens

School). So we did not

have any block lessons.

The trainees were about

half tool makers and the

other half radio

electronics technicians

and a technical draughts

woman.

Training contract

Philips 1974

to our workshop was a football field, then there was an outdoor pool and in

the cafeteria above the canteen were table tennis tables. These were

worked together. About once a week they were set up and then some

employees played table tennis after work.

And under the canteen, in the basement, was a bowling alley. By the way, the

employees were able to use the swimming pool for free in the summer with

the family on weekends. Also on the football field were games between e.g.

Footballers of Leitz and Philips or other teams discharged.

In the next six months, we also got to know the electric current and the

voltage and the resistance. When you do all three together, something like

Ohm's Law comes out. Of these laws and rules, there are more in the

business. The dangers of the electric current were taught to us. In the first

year of training, three of us spent a week on educational leave. Back then, it

was at company costs in the vicinity of Kassel to Jugendhof Dörnberg. There

we did everything for a week except playing with electrics. Another

educational leave with trainees from Philips took place about 1 year later in

Malente. After one year the first intermediate examination took place. The

apprentices from Philips and Leitz have made common cause. Otherwise we

only saw the colleagues from Leitz in the vocational school. Once at the

exams either the Leitz trainees came to Philips or the apprentices from

Philips went to the Hausertorwerk to Leitz. When the exam was over, it was

also in the training a little more electronic. We were also transferred from

the training workshop to other departments of the company for 3 months.

Picture gallery: Training Philips

The apprentices, the industrial clerk / woman learned, I have not seen after

the group picture. Gradually we got to know the company. Right next